·

Non-Destructive Testing Applications

Non-Destructive Testing

(NDT) is a term for describing a class of inspection methods for detecting defects

in objects or structures without destroying the original specimens.

Among the various NDT methods, radiography is one of the popular methods. Radiography uses X-rays and gamma-rays

to produce an image of a specimen on film, showing any changes in thickness, defects

(internal and external), and assembly details to ensure optimum quality in the operation.

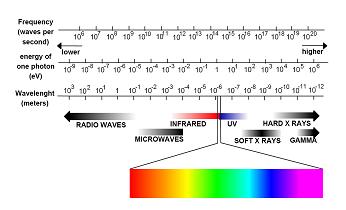

X-rays and Gamma rays are electromagnetic

radiation of exactly the same nature as light, but of much shorter wavelength. Wavelength

of visible light is on the order of 6000 angstroms while the wavelength of x-rays

is in the range of one angstrom and that of gamma rays is 0.0001 angstrom. This

very short wavelength is what gives x-rays and gamma rays their power to penetrate

materials that light cannot. This

high penetration capability of the rays allows us to see the internal conditions

of the object which cannot be seen from outside by naked eyes.

If an x-ray or gamma ray source is placed on one side of a specimen and a

photographic film on the other side, an image is obtained on the film of the thickness

variations in the specimen. This is

a well-established NDT technique and is widely used to detect internal flaws in

weldments and castings and to check for mis-constructions in assemblies

X-rays are produced by an x-ray

generator and is usually described by the electrical voltage across the x-ray tube. The higher the voltage, the greater

is the penetrating power of the radiation; industrial x-ray equipment ranges from

about 20KV to 20 MV and the most powerful equipments can be used to radiograph up

to 500mm steel. Nearly all gamma-radiography

is done with either cobalt-60 or iridium-192 sources.

To obtain good definition images, it is desirable to have small-diameter

radiation sources and the effective source size is in the range of 1 to 4mm diameter. After the radiographic film has been

exposed, it has to be photographically processed (develop, wash, fix and dry) and

is then placed on an illuminated screen for visual interpretation of the image. X-rays and Gamma-rays are

dangerous and must be used either inside a protective enclosure or appropriate barriers

and warning signals.

Site arrangement for carrying out radiography

The above photograph

shows a radiographic test carried out on a butt weld for a welder qualification

test.

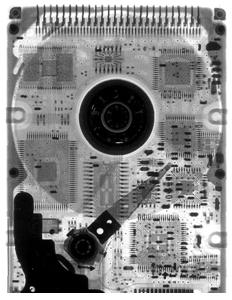

Radiograph of the internal structure of a hard disk

http://www.matsci.ucdavis.edu/MatSciLT/EMS-162L/images/Radiograph.jpg

References:

Ø

http://www.nei.org/howitworks/industrialapplications/

Ø

http://www.geinspectiontechnologies.com/en/products/x-ray/index.html

Ø

http://www.engineershandbook.com/MfgMethods/ndtrt.htm

Ø

http://www.ndt.net/article/mendt03/agfa/agfa.htm

Ø

http://www.ndt-ed.org/EducationResources/HighSchool/Radiography/hs_rad_index.htm

Ø

http://www.ndt-ed.org/EducationResources/CommunityCollege/Radiography/cc_rad_index.htm

Ø

http://www.ndt.net/ndtaz/ndtaz.php